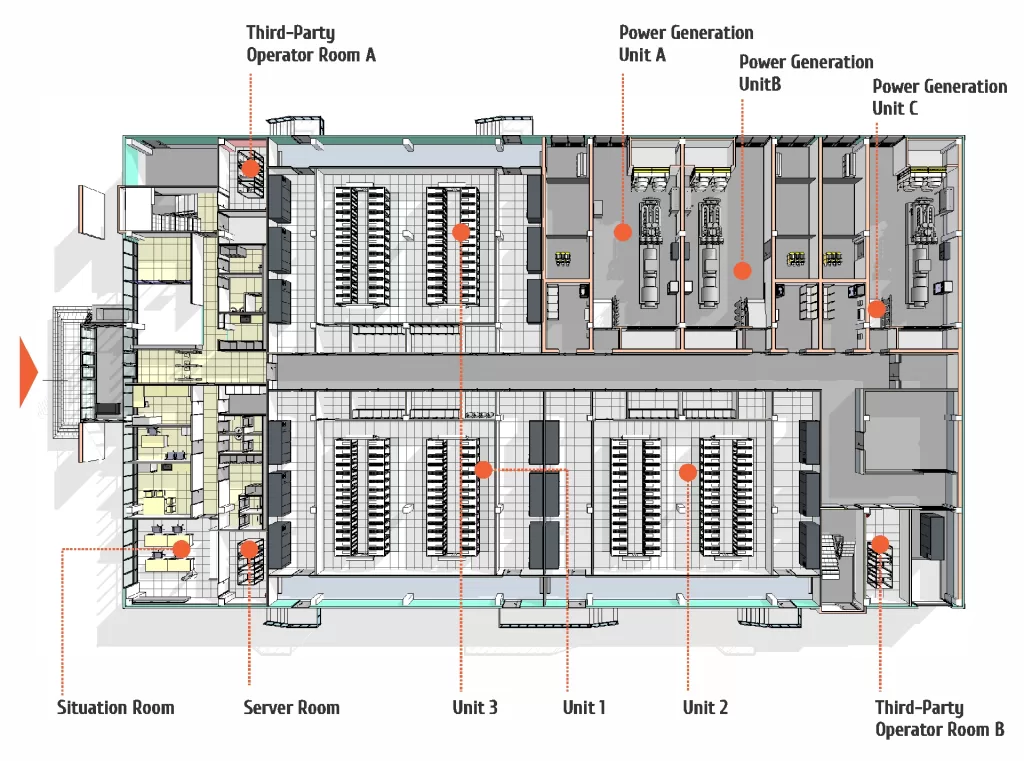

KEY INDICATORS

Number of stands

168

Total IT power

1 500 kW, 500 kW

for each machine hall

Maximum allowable power per one stand

up to 20 kW but not more than 500 kW

per one machine hall

Operating mode

24х7

Level of Uptime Institute Tier

III

Uninterrupted power supply is provided for all power consumers of the facility

PUE in warm season

1.3

PUE in cold season

1.05

DATA PROCESSING CENTER COOLING SYSTEM

Due to the high power density, the project provides for the liquid-type cold supply system, with the use of aqueous ethylene glycol solution, to prevent freezing in winter. Precision air conditioners are installed in air handling plants. 6 air conditioners are used for each machine hall; the redundancy level is N+2.

A total of 18 air conditioners and 18 chillers are installed at the facility. The Free cooling mode is provided.

UNINTERRUPTED POWER SUPPLY SYSTEM

To ensure uninterrupted power supply to all equipment of the Data Processing Center (servers, data storage system, active equipment, etc.), the project provides for the installation of three diesel-rotary uninterrupted power systems.

The full capacity of the uninterrupted power system is 2,720 kW, with the redundancy level of 3/2 N. при уровне резервирования 3/2 N.

SOLUTION FEATURES

- The machine hall is isolated from the utilities rooms (switchboard rooms and air handling plants) to limit the stay of engineers in the machine hall and, as a consequence, to reduce the number of incidents of different kinds.

- There is a two-level roof above the machine halls to eliminate leakages.

- To avoid complex ring topologies of the cooling systems, each chiller is equipped with one air conditioner. This allows maintaining simply the system, minimizing leakages, thus ensuring the ease of operation.

- The coolant temperature is 17–23 °С, which eliminates sweating on air conditioners, extends the period of free natural cooling and ensures the high efficiency of the chiller and air conditioner. машины и кондиционера.